Intelligent control technology compensates capacitive and inductive losses

Dipl.-Ing. (FH) Burkhard Dittmann, Industry Management Renewable Energies, Phoenix Contact Deutschland GmbH, Blomberg, Germany;

Dipl.-Ing. (FH) Maren Gast, Global Industry Management Solar Power, Phoenix Contact Electronics GmbH, Bad Pyrmont, Germany

In certain constellations, photovoltaic systems also generate capacitive power dissipations through the night. To ensure that reactive power does not have to be purchased from the grid operator in such cases, Phoenix Contact has developed the Q@Night control function, which is already in use in a PV park in Saxony-Anhalt, Germany.

ASG Engineering GmbH, based in Köthen in Saxony-Anhalt, Germany, specializes in the consulting, planning, implementation, and operational management of photovoltaic systems. Their range of services also includes integrating systems and storage systems into the existing infrastructure to ensure the optimized use of self-consumption. In addition, the company also specializes in peak load capping and storage solutions for micro-grid systems. However, building company-owned PV power stations is particularly important. Suitable areas are leased or bought for this purpose. So far, ASG Engineering has completed more than 100 projects related to roof and ground-mounted systems. One of the most recent projects is a 10-megawatt park in the Dessora Industrial Park in Oranienbaum-Wörlitz in eastern Saxony-Anhalt. “A photovoltaic system of this size is indeed something special,” says René Wollmerstädt, one of the two General Managers of ASG. “We have already installed 25 ground-mounted PV systems with a total output of more than 28 megawatts, but the power station in the Dessora Industrial Park is the largest one to date.”

The name “Dessora” is a tribute to the fact that the Industrial Park lies directly between Dessau and Oranienbaum-Wörlitz. Dessau is not only known to those interested in architecture due to the Bauhaus building designed by Walter Gropius in 1925/26. The city of Oranienbaum-Wörlitz is less well known. Its name is derived from an orangery that was first established in 1812 and that is still used today in its original function as one of the largest of its kind in Europe. The Dessora Industrial Park sits directly adjacent to the B107 road. Its proximity to the A9 motorway, the Leipzig airport 60 kilometers away, and an inland port in the vicinity provide good transportation connections. In addition to the photovoltaic park, food and waste disposal companies as well as a concrete and pellet plant have settled in the commercial and industrial park.

Controller ensures grid-compliant feed-in

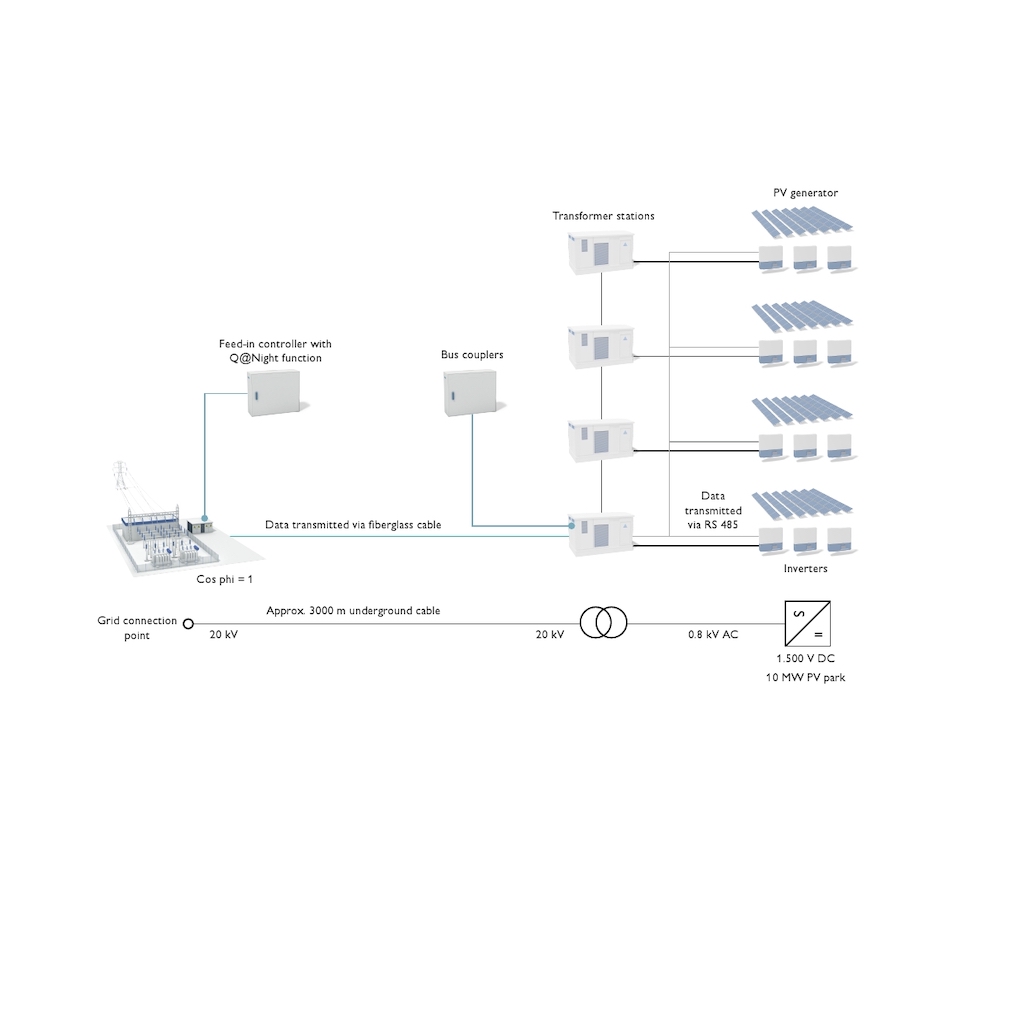

The 80 PV platforms belonging to ASG Engineering are situated between a pretzel bakery and the concrete plant mentioned earlier. On the largest of these platforms, 360 panels from the Chinese manufacturer Longi are arranged in rows of six. Half-cut solar cells are installed in the panels. This half-cut technology separates the solar panel into two identically sized twin halves which are connected in parallel in the center. This also halves the current per panel, which correlates with a reduction in the power loss in the cell. This lower power loss in turn increases the fill factor and efficiency of the cells, meaning that the energy yield is higher, in particular with strong solar radiation. The DC power generated by the PV panels is fed into a total of 37 Sungrow inverters, which convert the 1,500 V DC electricity into 800 V AC electricity. This AC electricity is then converted from the 0.8 kV level to the 20 kV medium-voltage level by four transformer stations that are distributed throughout the PV park.

Before the electricity can be fed into the grid, owned by Mitnetz Strom mbH, it must first be transmitted to the grid connection point three kilometers away via underground cabling. The Mitnetz Strom electricity grid covers an area of 30,804 square kilometers throughout the regions of Brandenburg, Saxony-Anhalt, South Saxony, and West Saxony. This grid reliably supplies a total of around 2.3 million people.

The Phoenix Contact feed-in controller based on PLCnext Technology is installed at the grid connection point. This device, certified in accordance with the German Directive VDE-AR-N 4110/4120, ensures that decentral power generation plants that are connected to medium and high-voltage grids feed in electricity in accordance with the grid requirements.

Reactive power no longer has to be purchased

Because both the hardware and software of the feed-in controller can be tailored and adjusted to project-specific requirements at any time, it was easy for the ASG employees to extend the device with Q@Night control function. The term Q@night comes from the concept of reactive power (Q) control at night. But why is this necessary at night, of all times, when the photovoltaic system cannot produce any solar power at all? As already mentioned, the grid connection point is three kilometers from the photovoltaic park.

Due to the long cable length, capacitive power losses occur, in particular at night. The transformers in the park also generate losses, in this case inductive power dissipations. Normally, the park operator would have to purchase reactive power from the grid operator to compensate such power dissipations. The financial outlay for such purchases would add up to a mid-range five-digit amount over the course of a year.

In such a case, it goes without saying that ASG Engineering takes countermeasures to minimize these costs. The Q@Night controller function programmed by ASG Engineering and integrated into the power generation plant controller now ensures that the inverters in the photovoltaic park do not shut down during the night, as is normally the case. Instead, they continue to provide reactive power in order to achieve a phase shift of precisely cos hi = 1 at the grid connection point. In this way, the inductive and capacitive properties of the park equipment – i.e., cables and transformers – are balanced.

Inverters receive instructions via RS485 communication

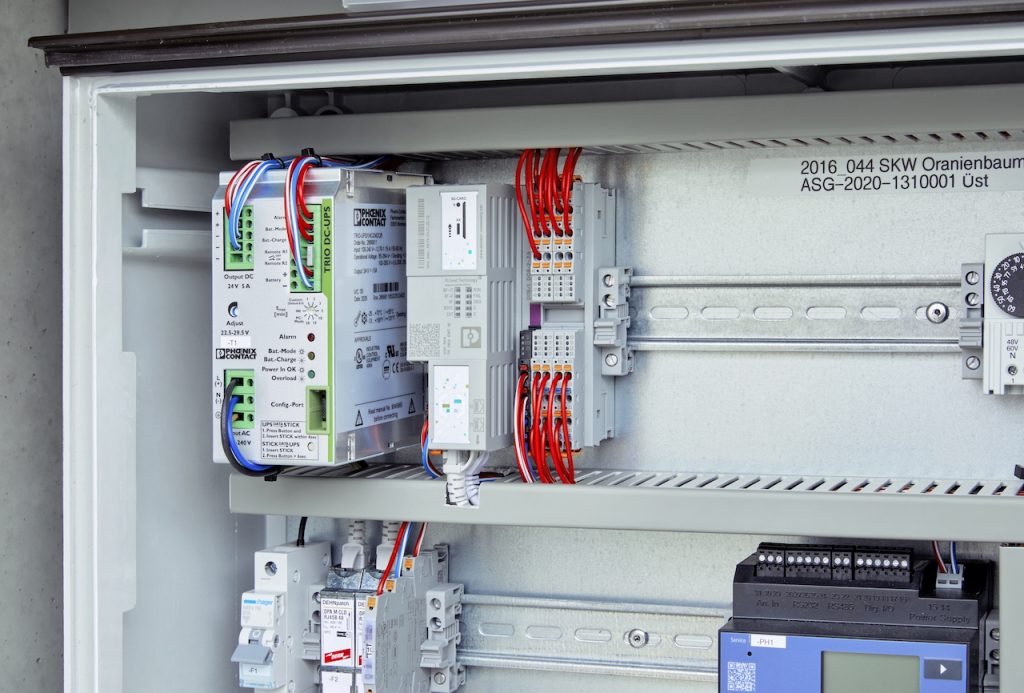

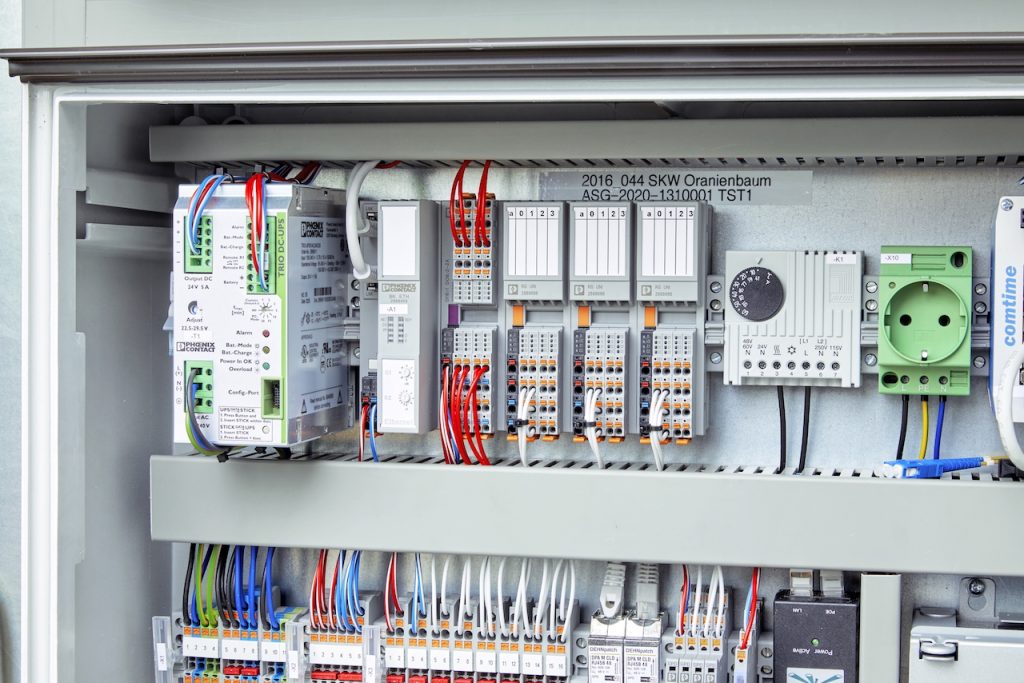

The control signals for the Q@Night control function are forwarded via a fiber-optic cable to an Axioline F BK ETH bus coupler, which is installed in one of the four transformer stations in the PV park three kilometers away.

RS Uni modules are aligned with the bus coupler and allow I/O devices with a serial interface to be operated on the bus system. The inverters, which are connected in a star configuration in 16 strings, receive the instructions required for both feed-in control and reactive power control at night from the bus coupler via RS485 data communication. “The Q@Night control function requires that the inverters support a suitable mode of operation at night,” explains Christopher Werlitz, the project manager responsible for the grid connection and communication at ASG Engineering.

Today, renewable power generation plants are now defining the landscape of a region in which 100 million metric tons of lignite were still being mined until the beginning of the 1990s. Generating energy from the sun – without emissions and effectively – was the challenge that prompted the two General Managers Jan Wecke and René Wollmerstädt to found ASG Engineering in 2007. Alexander Henze joined this successful company as a further General Manager in 2014. This trio operates with Wollmerstädt and Henze contributing their technical expertise, while Wecke, as a qualified banker, provides the commercial expertise. This combination has won over a large number of users. Wollmerstädt also envisions that the trend in the future will be towards plants the size of Dessora being the standard. Every single photovoltaic system, however, is unique. The General Managers of ASG are therefore happy that the solar power specialists from Phoenix Contact are always on hand to provide advice and support in all aspects related to the planning, installation, and grid connection.

Technology paves the way for the All Electric Society

Just like ASG Engineering, Phoenix Contact is also convinced that climate change can only be countered by switching completely from fossil to renewable energy sources. Here, the All Electric Society concept describes a future in which electrical energy generated from renewable sources is available worldwide as the primary type of energy in sufficient quantities and in an entirely economical way. This concept is based on the comprehensive electrification, coupling, and automation of all sectors of the economy and industry. With its components, systems, and solutions, as well as its digitalization expertise, Phoenix Contact is empowering industry and society to forge ahead with this transformation as we move toward a sustainable world.

Source: Phoenix Contact

Related Posts